Manufacture of Gears, Housings, and Reducers: From Design to Finished Product

At Molibden DOO, we pride ourselves on our ability to design and manufacture gears, complete housings, and reducers. The process begins in our engineering department, where a team of experienced engineers uses cutting-edge software to ensure optimal design and longevity of each component. As the project progresses, it moves to the skilled hands of our craftsmen, who execute the work using a combination of traditional and advanced machining techniques.

For the manufacture of gears, we use a wide range of machines, including:

Gear hobbing machines:

For precision tooth shaping.

Gear grinding machines:

For high precision and smooth tooth surface.

Milling machines:

For machining complex shapes and details.

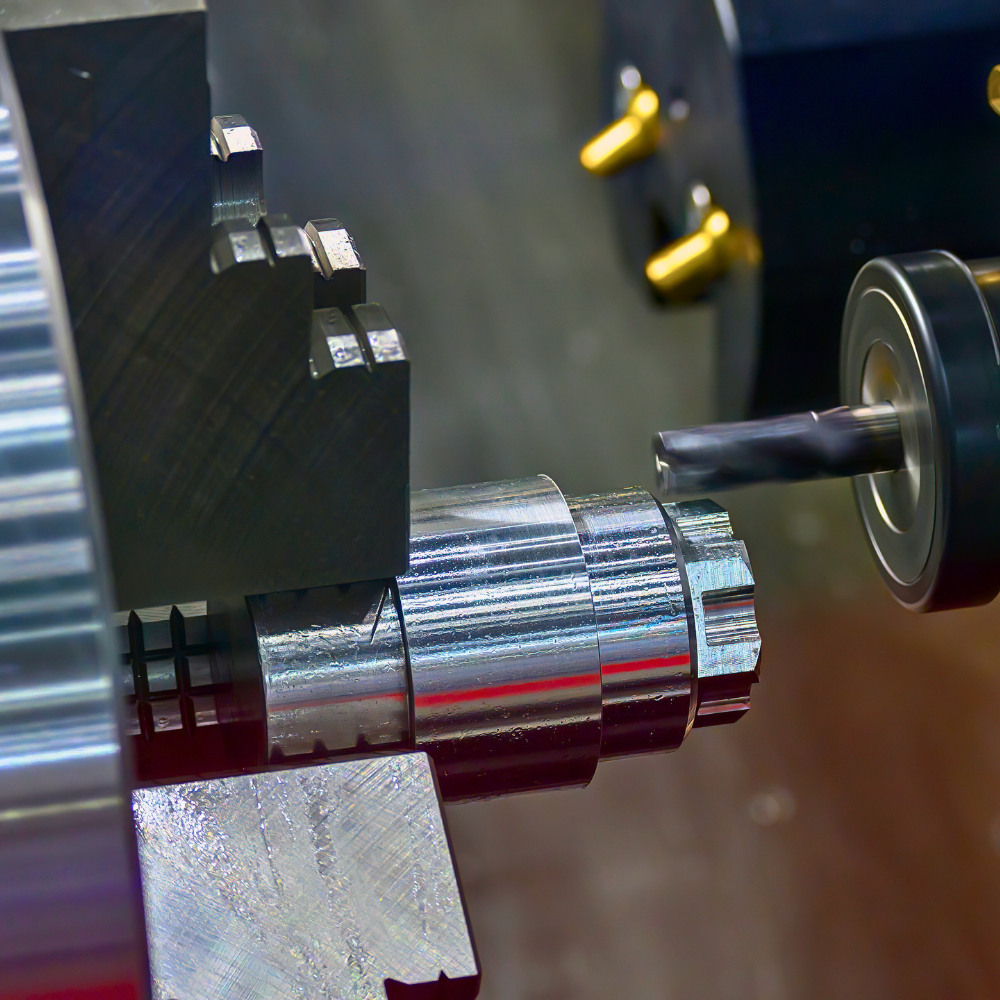

CNC machines:

For automated and high-precision machining of all components.

The process includes careful planning, precision material processing, and rigorous control of each step to maximize quality. Our team, with its vast experience and superior technology, guarantees the quality and precision of the manufactured components. The result of this process, from simple parts to complex assemblies, meets the critical needs of our clients with the highest quality and efficiency.

Manufacturing Process.